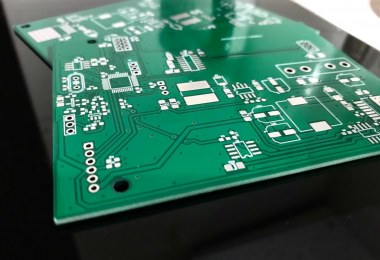

PCB protection - the right purpose

Anti-solder mask (soldermask) protects the printed circuit board against external conditions adversely affecting copper, prevents tin bridging and short circuits between pads, prevents and protects the glass fiber from overheating of the PCB during soldering in the furnace during the SMD / SMT assembly process. Once it could be done only in green. Many colors are available today. What color should I choose? Is it relevant to the design of electronic devices and their implementation in production?

Examples from life

We have a friend who orders a solder mask color for each type of circuit board. It all began with shades of blue, red, purple, then black, white, now purple, turquoise, burgundy ...

There is another customer - an enterprise with many departments. Each department chooses a mask color. It looks like every designer in this company prefers his own shade. Is that good or bad?

Similar "impressionist creation" can sometimes hinder and lengthen the electronic contract production. Why?

There is another customer - an enterprise with many departments. Each department chooses a mask color. It looks like every designer in this company prefers his own shade. Is that good or bad?

Similar "impressionist creation" can sometimes hinder and lengthen the electronic contract production. Why?

1. Difficulty with entry control

If a company performs visual inspection of printed circuits, differences in mask color can lead to a significant increase in personnel fatigue. First, bright colors, such as red or white, make your eyes tired, secondly, as the color changes, the mask saturation also changes, which means that it will be more difficult to distinguish the conductors underneath and control their quality. Thirdly, the eye, accustomed to identifying defects under the mask of one color, will not be able to find them in the same quality when changing colors.

Today, more and more often, automatic optical or electrical testers are used to control the performance of PCBs, which are much more accurate and faster than a human, so if the machine performs checks, the color of soldermask does not matter.

Today, more and more often, automatic optical or electrical testers are used to control the performance of PCBs, which are much more accurate and faster than a human, so if the machine performs checks, the color of soldermask does not matter.

2. Installation and exit control, production time

Slightly greater difficulties begin with the final visual inspection after installation. If the mask is black or white, and small elements such as 0402 are used - the quality control of their installation against a dark or black mask can be extended several times!

3. Quality of printed circuits

The default mask color is green. Therefore, every printed circuit factory has a supply of masks of this color in stock. But when the unusual color and shade of the mask come into play ("I ask for red, but not so purple, but lighter ..."), the manufacturer is forced to refine the appropriate mask based on existing inventory, or order from the supplier of materials. And it may happen that the consistency of dilution, application or hardener of this mask will result in much worse soldermask properties than the standard used. That is why you should carefully change the mask color for large batches, first try to make a change on a small series.

4. Aesthetics and practicality of electronics

We advise against using a white mask. After installing the components in the soldering oven, the PCBs acquire a yellowing tint.

We do not encourage using the red mask. The main disadvantage of this color is the difference in shades with repeated production - it is simply not easy for PCB manufacturers to hit the same shade of red.

Black and blue printed circuits look nice and very elegant in electronic devices, although, as we have already mentioned, they are more difficult in manual control visually.

We do not encourage using the red mask. The main disadvantage of this color is the difference in shades with repeated production - it is simply not easy for PCB manufacturers to hit the same shade of red.

Black and blue printed circuits look nice and very elegant in electronic devices, although, as we have already mentioned, they are more difficult in manual control visually.

5. Matte or glossy

The shiny mask is more comfortable, there are less visible scratches on it. PCBs with a shiny mask look more elegant.

Virtually every company that offers printed circuits by default suggests a green shiny mask by default.

In some situations, special colors should be used (for example, matte black is used on traffic lights to reduce glare, and white is used in lighting lamps to increase the light output). In such situations, it is justified to choose a non-standard color or matte / gloss.

Virtually every company that offers printed circuits by default suggests a green shiny mask by default.

In some situations, special colors should be used (for example, matte black is used on traffic lights to reduce glare, and white is used in lighting lamps to increase the light output). In such situations, it is justified to choose a non-standard color or matte / gloss.

Our suggestions

We advise at company level to analyze and choose the most suitable mask color and shade for electronic devices.

We consider green the optimal color - the most comfortable for the eyes and the most typical.

You should also consider one of the shades of blue.

We consider green the optimal color - the most comfortable for the eyes and the most typical.

You should also consider one of the shades of blue.