Cechy i różnice jednostronnych i dwustronnych płytek drukowanych

Single-sided and double-sided PCBs can be used to produce a wide range of modern products. The complexity of printed circuit board production depends on the number of pages. More complex multi-layer PCBs can then be created from one- and two-sided products.

One layers PCB

Such devices are mounted on one side only. In addition, the holes to which they will be attached must be non-metallic (smooth). The main area in which they are used are household appliances.

The main advantages of such plates are their affordable cost, as well as ensuring the highest accuracy in the implementation of the pattern formed by the conductive material and its connection with the holes. Negative aspects include the presence of low SMD and THT routing and assembly capabilities.

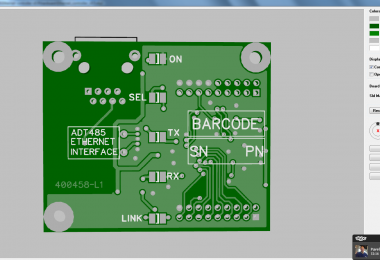

Two layers PCB

This type of tiles differs from the previous one in the arrangement of paths on both sides. The components are connected on both sides through so-called grommets. If there is no limit to the size of the board, you can design any device circuit. When installing elements on both sides of such a board, the need for clearance between the element housing and the base of the board should be taken into account.

Double-sided printed circuit boards may have non-metallic and metallized holes. According to this principle, they are divided into two types.

Devices with non-metallic holes are very similar to single-sided printed circuit boards. However, the second layer present on them helps to increase the system's routing capacity and component density.

Ensuring electrical transition between layers on such PCBs is rather problematic. It is necessary to use wire jumpers, rivets or soldering. For this reason, the installation of the circuit board is complicated and the price of the device increases. Most often, prototype and amateur devices are equipped with this type of printed circuit board.

Two layers printed circuit boards with metallized holes have high routing ability and allow efficient mounting of components close to each other. Such solutions are most often used in electronic devices.